GREATER PERFORMANCE, RELIABILITY AND COST-BENEFIT FOR YOUR PRODUCTS

We have solid knowledge in computational fluid dynamics and structural analysis, which allows us to identify critical points and opportunities for improvement in virtually any product with mechanical requirements.

Innovation

We believe that combining our experience and calculation capacity in several areas of mechanical engineering with the specific knowledge of our customers about their market niche, we can generate innovative and high value solutions.

Enhancement

We help you to understand better the limitations of your own products, identifying opportunities to make them technically more efficient and cost-effective.

Adequacy to national and international standards

If your product needs to meet some national or international standard (ISO, DIN, ANSI, etc.), we offer support from the interpretation of the standard to the development or adaptation of the project.

SERVICES

Our main services are computational analyses in different areas of mechanical engineering. However, we offer a complete development engineering cycle, which includes all steps from conceptual design to prototyping and testing.

-

Conceptual design

-

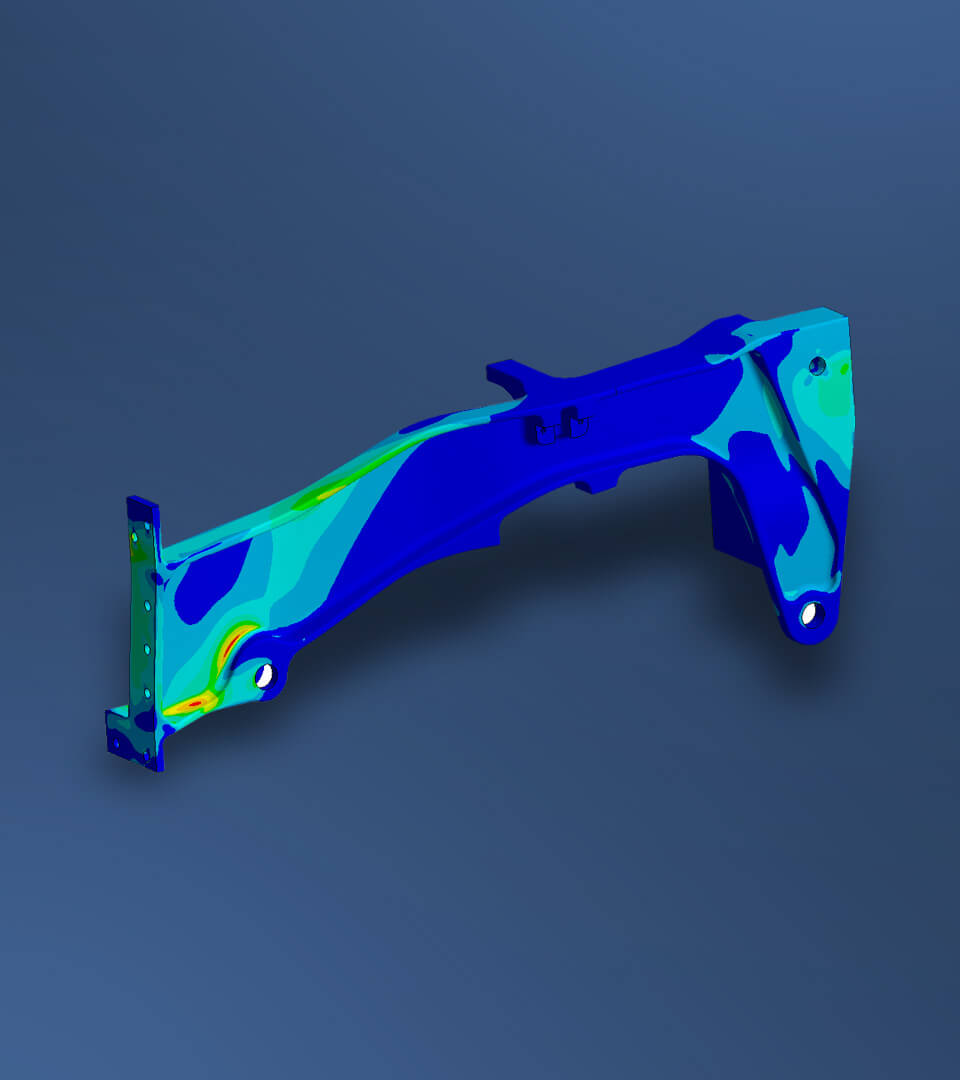

Static structural analysis (FEA)

-

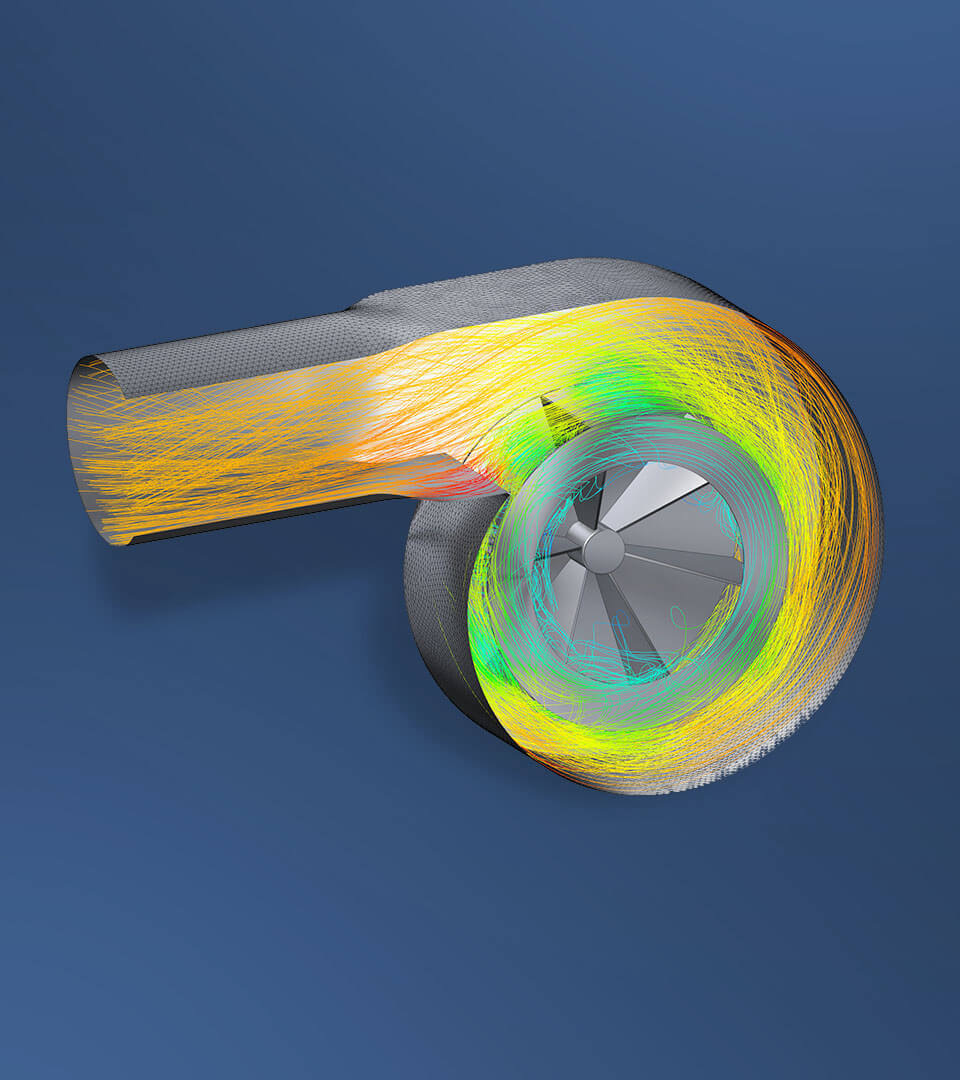

Computational fluid dynamics (CFD)

The conceptual design is the stage where a product gains its initial shape, being modeled in 3D with CAD software. The design is obtained using the product's requirements as guidelines, also taking into account to facilitate the manufacturing process. It is usual to realize iterations with computational analyses in this step, in order to enhance the design and to generate a degree of confidence that the requirements will be met.

A static structural analysis determines the effect of a load on a structural component or assembly, allowing to predict the stresses and deformations caused on it, as well as its safety factor. Examples of application: machine parts subject to high stress, metal structures, pressure vessels, etc.

Computational fluid dynamics (CFD) is a powerful tool that allows us to observe the flow of liquids and gases with a level of details usually hard to obtain in a test. It is useful for determining pressure losses, heat transfer, improving fluid mixing, improving aerodynamic performance, determining turbomachinery efficiency, among many others. Several phenomena can be modeled at the same time, such as chemical reactions, multiphase flows and particle tracking. Application examples: valves, compressors, turbines, fans, exhaust fans, heat exchangers, reactors, airfoils, room ventilation, piping, etc.

-

Modal analysis

-

Technical drawings

-

Prototyping and testing

A modal analysis determines the dynamic behavior of a component or system when excited by vibrations. The results are the natural frequencies of the system, with their respective modes of vibration. This information allows to adapt the project to ensure that the natural frequencies do not coincide with common frequencies in the operating environment, preventing the item from resonating. Examples of application: machines' structural components, metal structures, etc.

After the project is validated by the necessary analyzes and approved by the customer, we offer the possibility to produce the technical drawings of the developed components, letting them ready to be manufactured in series.

Depending on the application of the developed components, it may be necessary to produce a prototype and test it to validate its performance. Besides the manufacturing, we can also run the required tests, designing and producing special test benches when needed.

-

Support in international projects

-

Custom engineering tools

We have good experience dealing with international projects and teams that we can put at your service if there is a need for an engineer fluent in Portuguese, English and Spanish to be the link between your company and international partners.

When recurring calculations or dimensioning can be done analytically, without the need for numerical methods, tools such as a spreadsheet or an algorithm can be of great help. We can develop customized tools to solve specific problems in your daily work, generating the results, tables and graphs needed in an automated and fast way. Using programming languages, the possibilities are practically unlimited. Examples of application: screw sizing, calculation of reactions in a standardized geometry, determination of pressure loss in pipes, reading and treatment of large amounts of data, etc.

INSTITUTIONAL

The company

Marini Applied Mechanics (MMA) is a consulting firm in mechanical engineering which have the mission to help small and large companies of this segment to overcome their particular challenges and improve their products, contributing with the technical knowledge and experience acquired in over 10 years working in the industry. For an overview, we can group the areas we work in fluid dynamics, structural mechanics and heat transfer.

Having the quality of the offered services as our core value, MMA aims to be a reference in the process of developing and improving mechanical products. More than providing punctual support, our objective is to build long term partnerships with our clients, contributing for a broad and sustainable development.

CAN WE HELP YOU?

Contact Us

pt

pt en

en es

es